TWIN SHEET THERMOFORMING

Techniform Industries begins each project by identifying which plastic thermoforming process will meet a customer’s budget and quality criteria -

LET'S LOOK AT TWIN SHEET THERMOFORMING... LET'S LOOK AT TWIN SHEET THERMOFORMING...

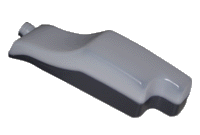

Twin Sheet Thermoforming is a process involving Vacuum Forming two plastic sheets simultaneously by utilizing opposing female molds, and bonding the two halves together while they are still hot. The result is a hollow finished piece which looks very similar to a blow molded product, but with several cost and manufacturing advantages.

|

Twin Sheet Forming

Process Candidates |

|

Advantages of

Twin Sheet Forming |

|

|

- Dunnage Containers

- Pallets

- Carrying Cases

- Double Walled

Floors

- Blow Molding

Prototype Development

|

- Increased Structural

Integrity and Rigidity

- Enclosed Cross-Section Capability

- Low Tooling Cost

- Internal Reinforcement

Options: Structural Member, Rigid Foam, Etc.

|

|

Discover images of Twin Sheet Forming and More When You Click to View Our Thermoform and Vacuum Form Parts Gallery

Or View Our Thermoforming Youtube Clip Galleria at YouTube.com Or View Our Thermoforming Youtube Clip Galleria at YouTube.com

Twin Sheet Thermoforming By Wickipedia -

Click to Read More | Click to Read At Wickipedia

Twin sheet forming is offered by Techniform, a leading thermoforming plastics manufacturer. Two plastic sheets are joined in the twin sheet thermoforming. The advantages of using plastic twin sheet forming rather than blow molding or rotational molding are mainly cost and appearance. Again, Twin-sheet thermoforming is a process of vacuum or pressure forming two sheets of plastic essentially simultaneously, with a separate mold on the top. A unique process in which two sheets of thermoplastic material are vacuum formed at the same time in the same machine and in the end producing one single welded plast thermoformed part. Click here to view some of our images of Custom Plastic Twin Sheet Thermoforming. |

Or View Our Thermoforming Youtube Clip Galleria at YouTube.com

Or View Our Thermoforming Youtube Clip Galleria at YouTube.com